Adhesive Applications in Fingerprint Sensor Modules

With the rapid advancement of technology, fingerprint recognition has become a standard feature across a wide range of electronic devices, including smartphones, laptops, cameras, smart locks, and safes. In daily life, fingerprint recognition is widely adopted due to its convenience and security. Currently, there are four main fingerprint recognition solutions: front touch, back touch, front slide, and back slide. Each solution has specific bonding and adhesive requirements.

Taking the iPhone 5s as an example, adhesives and precision dispensing processes are involved in several key bonding points, such as tactile switches, ID sensors, driver rings, and sapphire glass covers.

In this article, we will outline the key adhesive applications in fingerprint recognition modules and recommend suitable adhesive types, including UV adhesive (UV glue), low-temperature curing epoxy, and conductive adhesive.

Key Bonding Applications and Recommended Adhesives for Fingerprint Sensor Modules

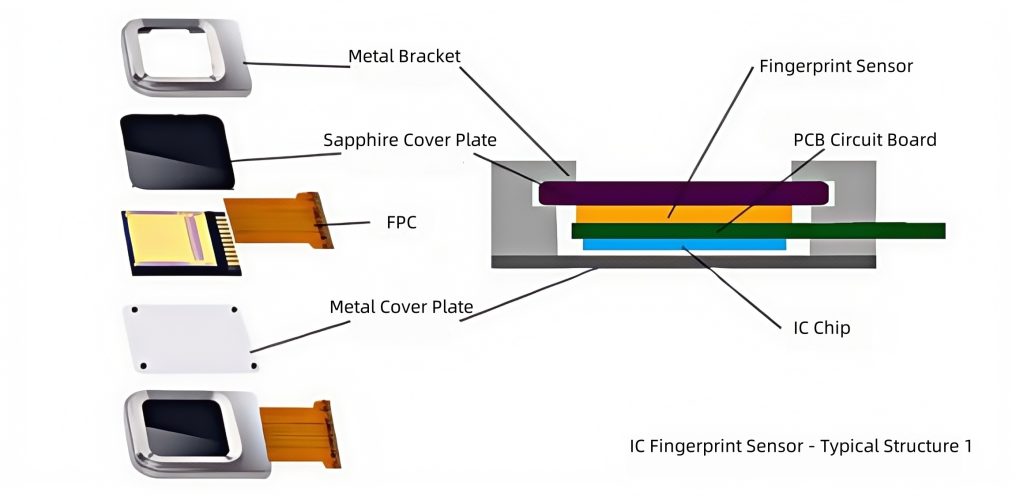

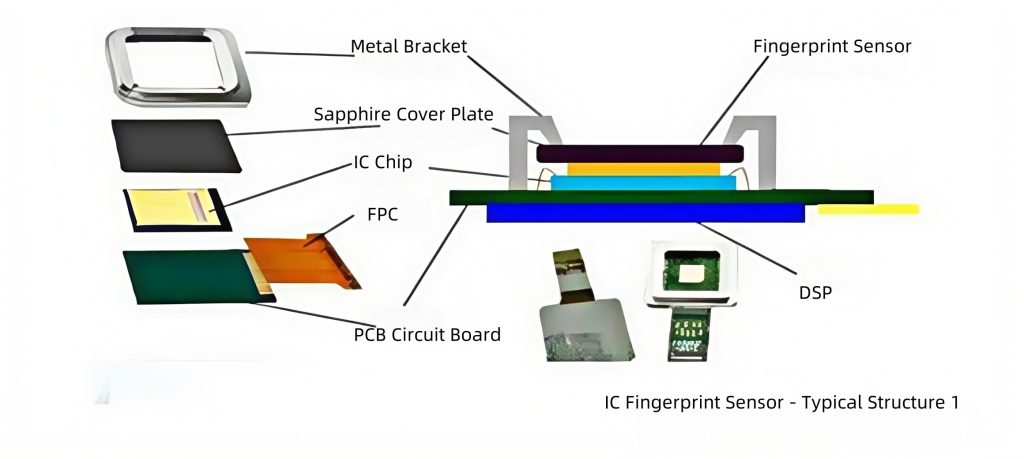

To better understand adhesive requirements, let’s first take a look at the typical structure of a fingerprint recognition module (see diagram below).

The main bonding points for fingerprint recognition modules in smartphones are as follows:

- Metal ring/frame to FPC substrate fixation: Recommended adhesive – low-temperature curing epoxy.

- Sensor to PCB bonding: Recommended adhesive – low-temperature curing epoxy.

- FPC component encapsulation and reinforcement: Recommended adhesive – underfill adhesive or UV adhesive.

- Fingerprint sensor chip underfill (sensor/wafer to FPC bonding): Recommended adhesive – underfill epoxy.

- Glass bonding: Recommended adhesive – UV adhesive (UV glue).

- Sapphire glass to sensor fixation: Recommended adhesive – single-component high dielectric epoxy.

- FPC dispensing with conductive path to metal ring: Recommended adhesive – conductive adhesive.

As fingerprint recognition technology continues to evolve, the performance requirements for adhesives—including strong bonding, precision dispensing, fast curing, electrical conductivity, and environmental resistance—are becoming more critical. Among them, UV adhesive plays a key role in glass bonding and component encapsulation, enabling manufacturers to achieve high reliability and fast production cycles.