In the field of medical device manufacturing, the reliability and safety of adhesive technology are critical. Hypodermic needles, as key components that come into direct contact with the human body, require high-precision bonding to ensure both patient safety and treatment effectiveness.

Our medical-grade UV adhesives have become the preferred choice for many medical device manufacturers thanks to their superior performance. They are widely used in the production of medical needles. This article shares a real-world case study highlighting the application and advantages of our UV adhesive in hypodermic needle bonding.

Case Study: Medical Needle Bonding with UV Adhesive

A leading medical device manufacturer in Zhejiang, China, specializing in disposable hypodermic needles, faced challenges with traditional adhesive processes, including slow curing speed and insufficient bonding strength. The customer approached us seeking a more efficient and reliable adhesive solution for needle bonding.

After technical evaluation and in-depth consultation, we recommended our high-viscosity medical UV adhesive, designed for precise dispensing on small bonding areas like hypodermic needles. Paired with our UV LED curing system, this solution enabled rapid curing. We also provided process optimization support by integrating adhesive dispensing and curing steps into their production line.

Results

By replacing their original adhesive with our UV bonding solution, the manufacturer achieved:

- Compliance with medical industry bonding strength standards with no detachment issues.

- Reduced adhesive consumption and lower scrap rates, resulting in cost savings.

- 30% higher production efficiency thanks to fast UV curing.

Key Advantages of Our Medical UV Adhesive for Needle Bonding

- High Bonding Strength – Ensures needle safety and reliability during use.

- Rapid UV Curing – Supports high-volume automated production.

- Certified Biocompatibility – Meets medical industry standards and is safe for human contact.

- Chemical Resistance – Withstands disinfectants and harsh cleaning agents.

- Precision Bonding – Suitable for micro-scale bonding in delicate medical devices.

Extended Applications in Medical Device Manufacturing

Our medical-grade UV adhesives are not only ideal for hypodermic needle bonding but are also widely used in other areas of medical device production:

- Catheter Bonding – Delivers strong adhesion and chemical resistance to ensure sealing integrity.

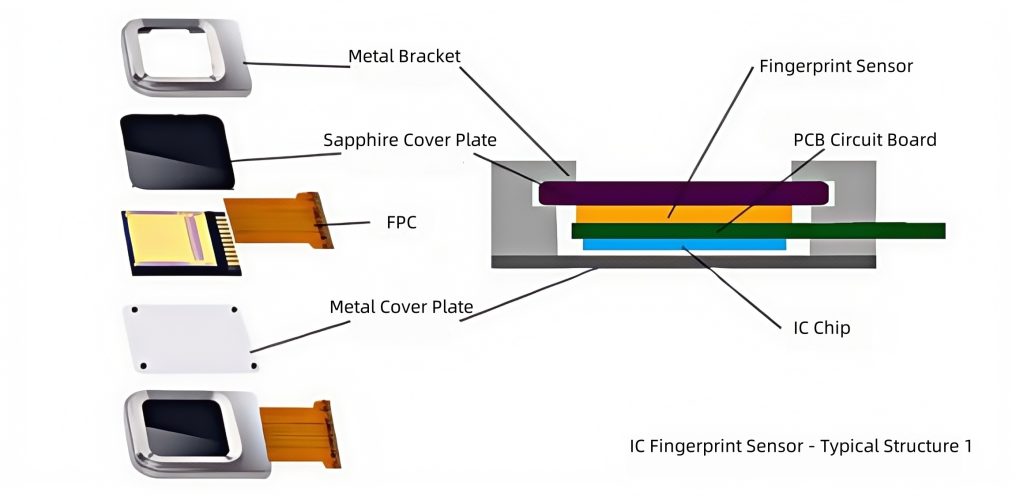

- Sensor Encapsulation – Protects sensitive medical sensors from environmental damage.

- General Medical Device Assembly – Provides precision bonding and sealing for various medical components.